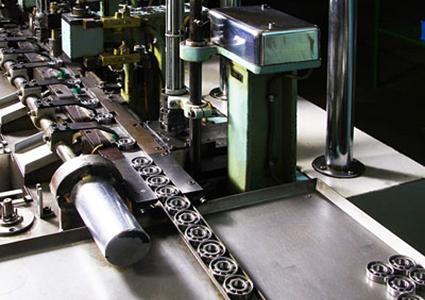

Manufacturing of bearings

Manufacturing of bearings is assured and ensured according to the related national and international dimensional and material standards, internal regulations and standards of company assuring the quality management system according to STN ISO 9001. Increasing dynamical load of bearing through improving semi-finished material part properties is a determining factor for the future bearing lifetime.

Български

Български Česky

Česky Deutsch

Deutsch English

English Español

Español Français

Français Polski

Polski Русский

Русский Slovensky

Slovensky Український

Український